PROJECTS

Hillyard Warehouse

St. Joseph, Missouri

For this large warehouse structure, the geotechnical challenge is deep, soft, wet soils. My client, the general contractor, had to lift some very heavy concrete wall panels into place. The heaviest panel weighs 95 tons, and the crane used to lift them weighs 260 tons. My job was to make sure the crane did not sink into the ground when making the heavy lifts. I designed bearing pads under the crane tracks. These pads consist of 1 to 5 feet of crushed limestone, layers of geogrids, and layers of large wood timbers.

Foundation Settlement at Commercial Building

Lawrence, Kansas

A 30-year-old three-story commercial building in Lawrence, Kansas has recently experienced some foundation movements. This has caused damage to the floor slab and exterior walls. I am working for the owner to determine the cause of the settlement and alternatives to stop further movements. The building is on a hillside that has recently experienced slope failures that have undermined the footings. We are developing plans to stabilize the hillside and underpin the foundations.

Construction Haul Roads, Piper High School

Kansas City, Kansas

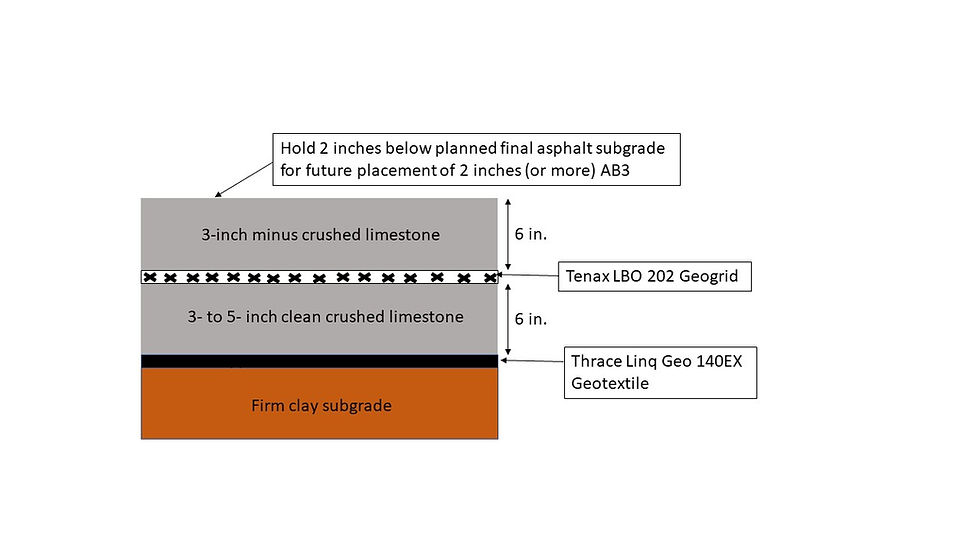

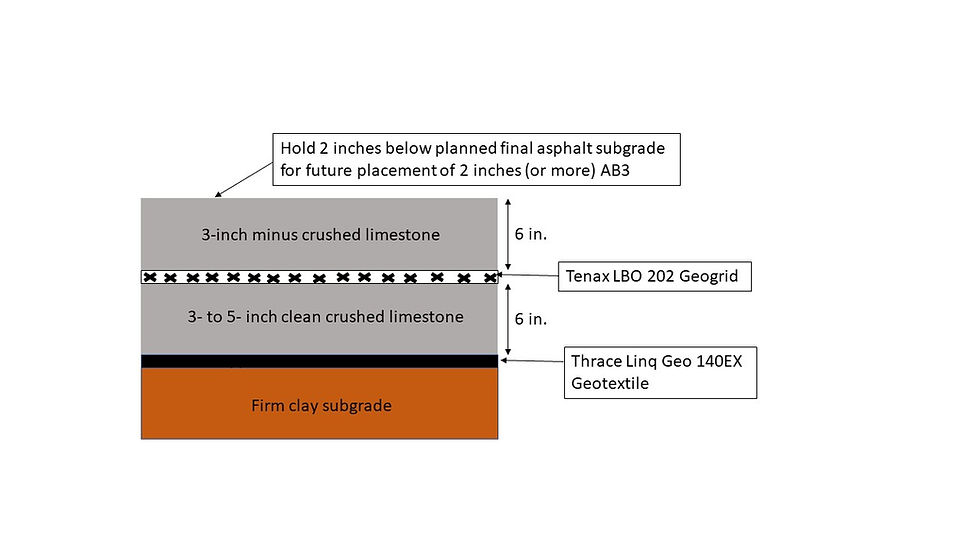

The soft silty soils at this project site make it difficult for heavy trucks to deliver construction materials such as asphalt, crushed rock, and precast concrete wall panels. The delivery trucks get stuck in the mud. To solve this problem, I designed haul roads for the general contractor. The roads consisted of 12 inches or large-sized crushed limestone with one or two layers of geogrid, and a filter fabric geotextile separating the road from the underlying soft clay. These haul roads allowed the contractor to have over 300 heavy trucks deliver materials to the site with no problems. These temporary roads were then included as the base material below the permanent asphalt pavements, providing a more durable permanent pavement for the school.

Changed Subsurface Conditions Claim, Confidential Project

Missouri

A general contractor on a large industrial project was uncertain how to handle a claim of changed subsurface conditions from the storm sewer contractor. The claim included a cost increase of over $200,000. The deep excavations for the storm sewers had encountered groundwater and unstable sands. Working for the general contractor, I provided a geotechnical engineering and geologic evaluation of the claim, reviewed the subsurface information in the contract documents, and assisted with their negotiations on this claim.

Construction Excavation Stability, Shamrock Project

Overland Park, Kansas

OSHA provides clear guidelines to contractors regarding the stability of temporary construction excavations. However, sometimes sights are too crowded to meet the OSHA guidelines. When it is necessary to dig deeper or steeper than allowed by OSHA, a licensed geotechnical engineer is needed to review and approve the excavation plan. For this project, I evaluated the stability of the deep, steep excavations, including excavations that extended under the foundations of the existing adjacent building. Where the excavation was stable, I provided the engineering approval. Where the stability was a concern, I provided guidance on how to revise the excavation plan to provide adequate stability. I worked with the on-site safety personnel to help them with their daily monitoring of these excavations.

Changed Subsurface Conditions Claim, Confidential Project

Nebraska

When constructing a deep pipeline, a contractor was surprised to encounter buried rubble. Pieces of limestone rock as wide as 6 feet were present at depths of 10 to 25 feet throughout a project site. The subsurface information (i.e., boring logs) included in the construction documents had not indicated that this rubble was present. These large rock fragments significantly complicated the excavations that were necessary to construct this pipeline, increasing costs by over $500,000. I assisted the contractor with their evaluation of the subsurface conditions, how those conditions were communicated in the construction documents, and their negotiation of a change order with the owner.

Third-Party Geotechnical Engineering Peer Review, University of Wyoming Student Housing

Laramie, Wyoming

I have completed over 400 third-party independent geotechnical peer reviews for general contractors over the past 17 years on projects throughout the central USA. These peer reviews are vital tools for reducing subsurface risk. The peer review evaluates the geotechnical report and construction documents to assist contractors in the identification of geotechnical concerns, inconsistencies, and areas where clarification could benefit the project. For this one in Laramie, Wyoming, the primary geotechnical concerns were the presence of rubble fill throughout the site, the need for significant shoring of the basement excavation, and the heavy foundation loads for the six-story dormitory. I helped the contractors prepare for these concerns in their budgets and plans.

Annual Assessment of Underground Stability, Downtown Underground

Kansas City, Missouri

Bedrock GeoConsult provides annual geological engineering stability assessments for underground facilities. The Kansas City area has many underground commercial, industrial, and storage facilities. These spaces are constructed in former underground limestone mines. Municipal codes require annual evaluation of the stability of the underground space by a licensed engineer. The condition of the rock mass including groundwater seepage, cracks and joints, and movements of the floor, roof, or support columns must be reviewed. The engineer provides guidance on improvements or maintenance needed to maintain stability.